In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

Automatic marking machine

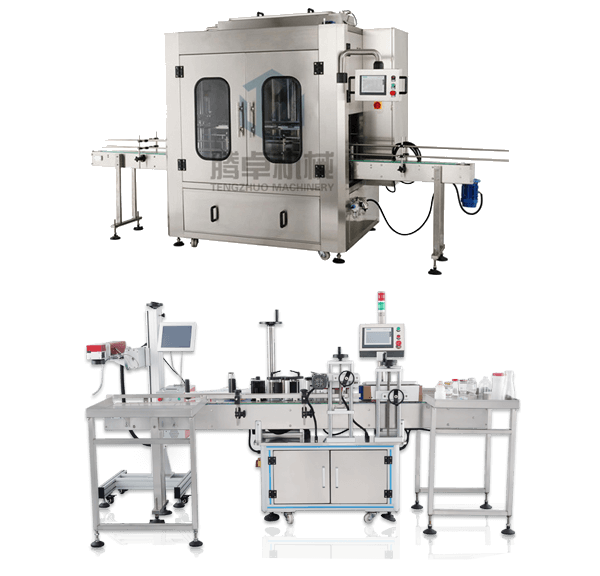

Automatic labeling machine, this series of equipment is a set of bottle feeding, sub-bottle, set label, shrink label function in one of the automatic intelligent packaging line, real high-speed, accurate positioning, manpower simplification, perfect packaging is the spirit of this equipment design, suitable for beverage and health food factory, with beautiful, easy to clean and maintain Function

Synchronous mechanism transmission, any transmission belt replacement can be quickly completed, with the traditional multi-layer linkage (replacement and maintenance needs more than six hours) easier to maintain, simple maintenance, never affect production.

The unique cutter base design in China is suitable for the container of

Single contraction label feeding tray design, moderate height, easy to install labels; Microcomputer automatic calculus, no setting, no adjustment, as long as a touch, the label can be automatically detected, automatic positioning; Change the label absolutely fast and labor-saving, cutting position absolutely accurate.

feeding mechanism: dynamic synchronous tension control supply label, supply capacity 90 m / min, coil supply plate 500 mm, paper tube diameter 4′, 8′, 10′, feeding stable tension mechanism design, ensure the accuracy of cutting length, supply stability, fast, ensure the accuracy of marking and marking.

The servo marking mechanism of the L central pillar, the marking speed is 260B bottles / points.

The new cutter design uses servo motor drive, high speed, stable and accurate movement, smooth incision, beautiful contraction, with the tag synchronous positioning mechanism, incision positioning accuracy as high as (+1 mm).

Multi-point emergency stop button, can be installed in the appropriate position on the production line emergency stop button, so that the linkage is safe and smooth production.

Special design hot air type shrinking furnace, using high pressure blower, special hot air contracting ring duct is more energy-saving, shrinkage effect is incomparable, if the traditional shrinking furnace can not shrink the curve bottle, by this hot air type shrinking furnace can be satisfied with the smooth shrinkage effect.

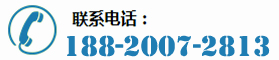

The new type steam shrinkage furnace has greatly improved the heat shrinkage efficiency. According to different and irregular cylinder, square bottle, flat bottle and other bottle shapes, it is easy to adjust, maintain, shrink smoothly. Can be adjusted to achieve the most perfect state of contraction effect. The low pressure distributor drum is designed with seamless steel pipe, and the connecting pipes are made of stainless steel hose quick connector, which is convenient for disassembly and installation. The shell of the machine is made of stainless steel and kept warm. It not only saves energy, but also conforms to international safety standards. The condensed water of the stainless steel water receiving plate at the bottom can be discharged by pipes. The working environment is not affected. The box has two windows in front and two in back. The whole machine adopts waterproof design, which is made of stainless steel and easy to operate and maintain.

technical parameter:

l Applicable product range: outer diameter 20~34 (mm) height 50~120 (mm)

l Applicable label range: 35 mm in diameter (different sizes need to be replaced), 70 mm long.

l Cutting accuracy: ± 1 mm (excluding product and label errors)

l Production capacity: 100~200 bottles / min.

l Voltage: 220V (three phase four wire)

l Whole machine power: 3KW shrink machine: 8KW

l Whole machine size: 4000X800X1950 (mm) (long X width X high)

l Weight of whole machine: 400kg

The main technical parameters of the equipment are:

Voltage specifications: 1, host: AC220V, 50 / 60HZ, 1.5 – 2KW, single phase

Or host: AC380V, 50 / 60HZ, 2KW, 3 phase.

2. Shrink furnace: AC380V, 50 / 60HZ, 15KW (electrothermal) / 3 phase.

Production speed:

The standard length of the label is 100mm, and the production speed can be determined according to the customer’s needs. The standard speed can be divided into 100 bottles/min and 200 bottles/min.

Bottles / points, 300 bottles / points, 400 bottles / points, 500 bottles / grading series.

The shorter the length of M tags, the faster the production speed.

Bottle diameter: 28mm~ 125mm

Label length: 30mm ~250mm

Label thickness: 0.035mm ~0.13mm

Labelling materials: PVC, PET, OPS

Equipment size:

1. The size of the header is L3500mm * W850mm * H1950mm

2. Steam shrinkage furnace: steam consumption: 50Kg / hr.

Steam pressure: 1Kg / cm

Steam shrinkage furnace volume: L1200mm * W500mm * H1500mm

3, heat shrinkable furnace volume: L1200mm * W500mm * H1600mm

Power: 10KW ~15KW

Voltage: 3380VAC

4. Steam generator technical parameters:

|

Specification parameter |

GBP-18 |

GBP-24 |

GBP-36 |

GBP-48 |

|

|

Rated evaporation |

24 |

32 |

48 |

64 |

|

|

Rated steam pressure |

0.4/0.7 |

0.4/0.7 |

0.4 |

0.4 |

|

|

Rated steam temperature |

151/170 |

151/170 |

151 |

151 |

|

|

Water supply temperature |

20 |

20 |

20 |

20 |

|

|

electric power |

18KW |

24KW |

36KW |

48KW |

|

|

Motor power of feed water pump |

550 |

750 |

750 |

750 |

|

|

Boiler water volume |

42 |

||||

|

External dimensions (MM) |

600x600x1280 |

950x550x1400 |

|||

|

Boiler weight |

91kg |

100kg |

|||

|

|

|

|

|

|

|

(above is standard type technical parameters, other special requirements and functions, can be customized!)

Filling machine

Filling machine Labeling machine

Labeling machine Screw cap machine

Screw cap machine Casing shrink..

Casing shrink.. Bottle washing..

Bottle washing.. Automatic medicin.

Automatic medicin. Automatic filling ..

Automatic filling ..  Automatic filling ..

Automatic filling ..