In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

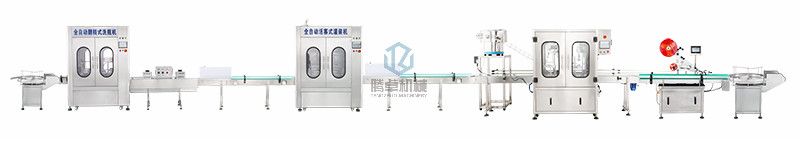

Washing, drying, filling, labeling, marking and marking production line for alcoholic drinks

The characteristics of the automatic alcoholic packaging production line are:

1. Automatic production line flow: manual bottle on the bottle feeding turntable – automatic bottle washing – automatic high temperature drying sterilization – manual light inspection – automatic filling – automatic capping – automatic capping – automatic marking – Manual bottle closing

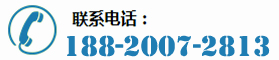

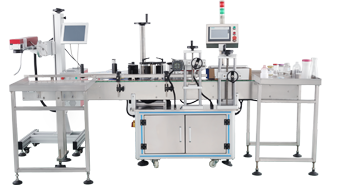

2. the line is washed with flushing bottle and rinsed in high pressure.Servo-driven piston quantitative filling is adopted in filling. It is easy to maintain without leakage and pollution, high filling precision and stable filling.The rotary cover adopts vacuum pump cover with vacuum pump. The vacuum degree is high and the equipment is simple to adjust.Code is coded by laser, environmental protection, production date will never fade, and maintenance is simple.Labelling uses servo motor and imported electric eye induction, accurate marking, high precision labeling, flat wrinkle.

3. The whole line is made of food-grade stainless steel, which is easy to clean and disinfect, and conforms to the state regulations and requirements on food machinery and food hygiene.The overall plexiglass cover is designed to prevent impurities from entering the filling material and is safe and hygienic.

4. technical parameters:

(1) bottle width: customized according to customer’s products.

(2) bottle height: can be customized according to customer’s products.

(3) filling capacity: 100-1000ml (other specifications can be customized as required).

(4) number of filling heads: customized according to production requirements.

(5) filling accuracy: + 1% (equal capacity filling)

(6) production speed: customized according to production requirements.

(7) air pressure: 0.6-0.8Mpa

(8) air consumption: 200 litres / min.

(9) power supply: 380V/50HZ, three-phase five wire system.

(10) whole line power: 23KW

This product line is also suitable for packaging of sauce, chili sauce, fruit juice and other foods.

Recommend

-

Honey filling capping aluminum foil sealing marking

-

Washing, drying, filling, labeling, marking and marking production line for alcoholic drinks

-

Enzyme washing, drying, filling and locking cover marking production line

-

Filling vacuum marking cover for soy sauce

-

Instant bird’s nest washing, drying, filling, screwing, marking, labeling and marking production line

Filling machine

Filling machine Labeling machine

Labeling machine Screw cap machine

Screw cap machine Casing shrink..

Casing shrink.. Bottle washing..

Bottle washing.. Automatic medicin.

Automatic medicin. Automatic filling ..

Automatic filling ..  Automatic filling ..

Automatic filling ..